Back

German Federal Minister for Housing, Urban Development and Building visits KUKA to talk about automated house construction

17 Oct 2024

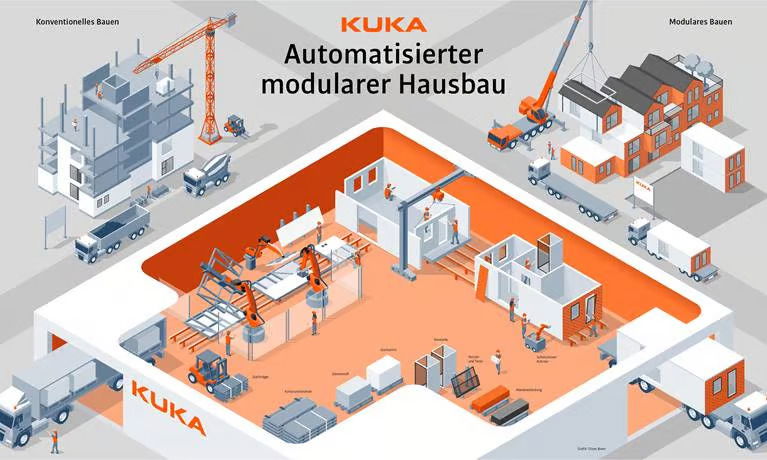

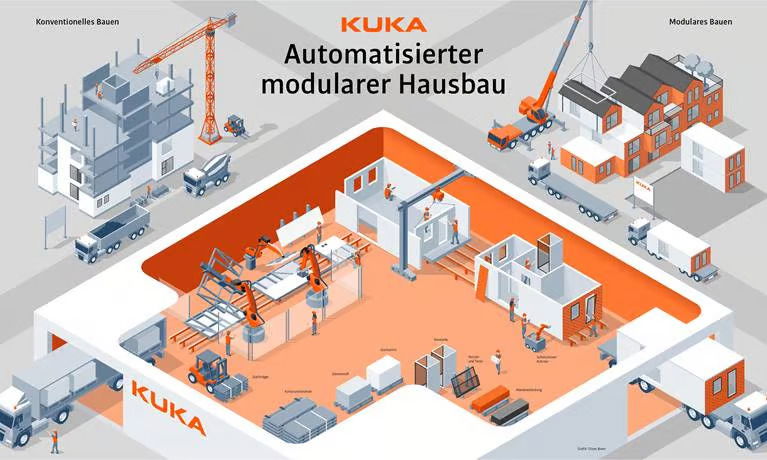

A shortage of living space, rising costs, and a lack of skilled labor are some of the key challenges confronting society today. Automated modular house construction presents a promising solution to these issues. During a recent visit to KUKA, German Federal Minister for Building, Klara Geywitz, was introduced to this innovative concept and its potential to address housing needs efficiently and sustainably.

Automated house building shifts much of the construction process from the building site to the factory. Using robotics and advanced automation, entire housing elements are manufactured on an assembly line in a highly digitized and efficient manner. These pre-produced elements are then assembled at the construction site, streamlining the process and significantly reducing on-site labor and time.

" At KUKA, we are applying the automation and systems expertise we have built up over decades to the construction industry. And this innovative concept offers enormous potential." - Timo Heil, CEO KUKA Systems EMEA

Automated modular house construction dramatically shortens building time and lowers costs, addressing the shortage of skilled labor while conserving resources. This approach also offers new opportunities for enhanced sustainability, making it a forward-thinking solution to current challenges in the construction industry.

"With the use of robotics, living spaces can be built faster, more sustainably and more cost-effectively. In view of the shortage of skilled workers and the high demand for living space, we need more digitalization in the construction industry. KUKA is showing how modern automation technologies can advance modular house construction and thus make construction fit for the future." - Federal Minister Klara Geywitz

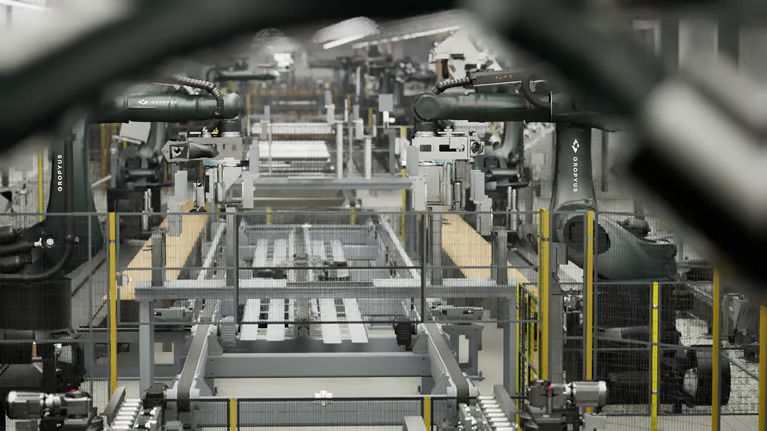

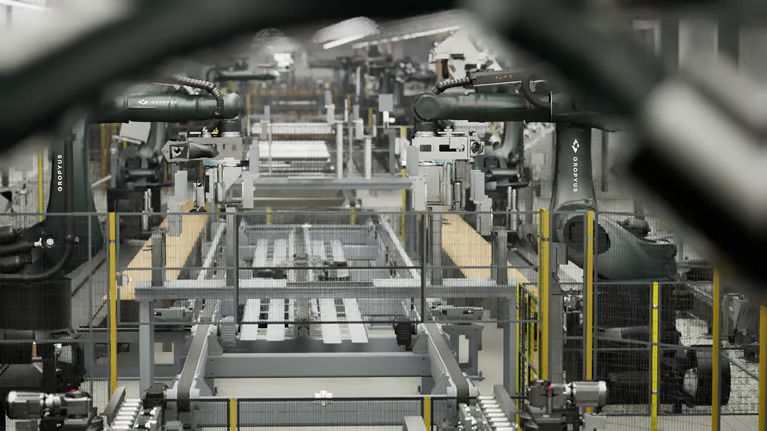

Unique House-Building Factory

This groundbreaking construction concept is already becoming a reality. KUKA is developing a turnkey, flexible system featuring 50 robots in the world's first smart factory of its kind, owned by GROPYUS, located in Richen, Baden-Württemberg. Starting in 2025, the factory will digitally plan multi-storey, sustainable timber-hybrid apartment buildings and produce them on an industrial scale with a high level of automation. These buildings will then be assembled on-site using automated systems. Leveraging KUKA's technologies, GROPYUS will create more than 3,500 apartments annually, setting a new standard for efficient, sustainable housing production.

Share: