Back

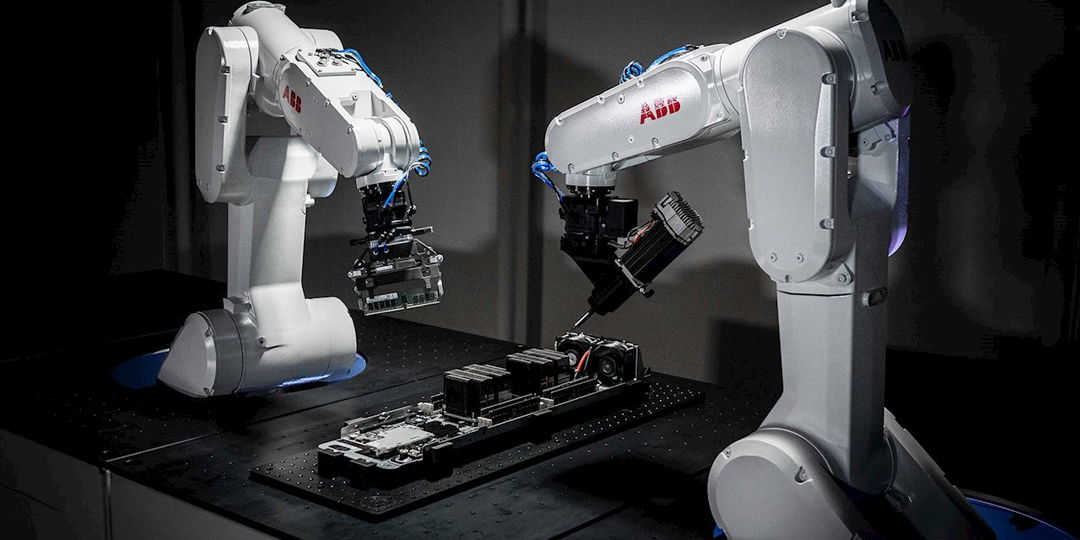

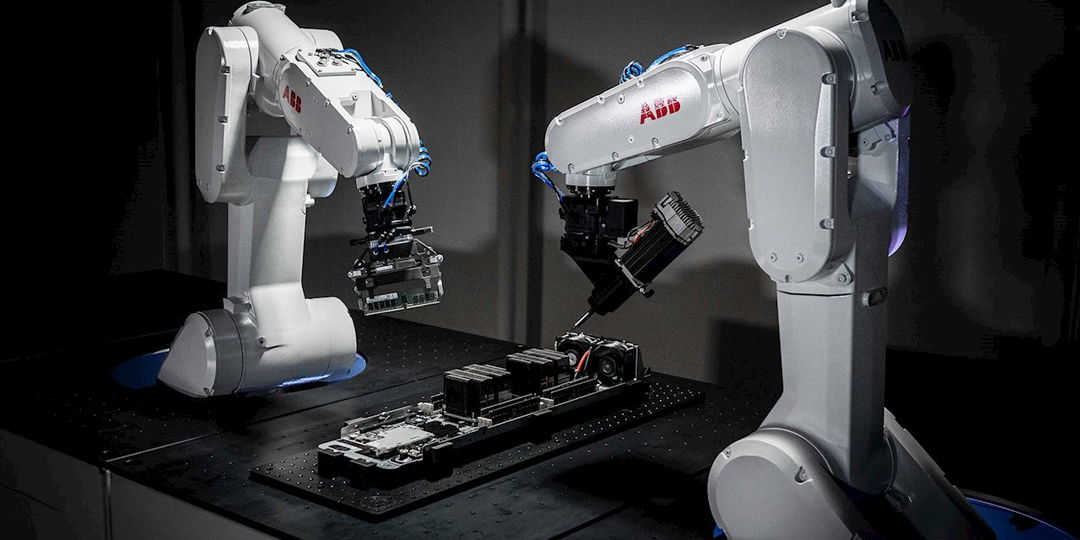

ABB Robotics and US start-up Molg tackle data center e-waste with robotic microfactories

17 Oct 2024

ABB Robotics is partnering with U.S. start-up Molg to develop robotic microfactories that will recover and recycle discarded electronic equipment, or e-waste, from data center operators. With global e-waste expected to reach 75 million tons by 2030, these microfactories will play a crucial role in reducing electronic waste and promoting sustainability in the data center industry.

Craig McDonnell, Managing Director of Business Line Industries at ABB Robotics, highlighted the importance of this initiative: "Our collaboration with Molg supports our vision of helping organizations operate more efficiently and sustainably. By developing new applications for industrial robotics, we are addressing a growing market with circularity and sustainability at its core. Our solution enables the automated disassembly and upgrading of data center equipment, promoting greater circularity through responsible disposal, recycling, and reuse of components."

As advancements in computing—such as AI, machine learning, and cloud technology—demand frequent upgrades in data centers, these facilities contribute significantly to the 2.6 million tonnes of e-waste generated globally each year. ABB Robotics’ collaboration aims to mitigate this impact while enhancing sustainability in the sector.

ABB Robotics is committed to fostering innovation ecosystems through collaboration and venture capital investments. Recently, ABB Robotics & Automation Ventures (ABB RA Ventures) invested in Molg’s seed round, which was led by Closed Loop Partners’ Ventures Group and included participation from Amazon’s Climate Pledge Fund, Overture, Elemental Impact, and Techstars Ventures.

Molg was recognized as a winner in ABB’s Motion drive business during the ABB Accelerating Circularity Startup Challenge 2023. The company's robotic microfactory is capable of autonomously assembling and disassembling complex electronic products, such as laptops, servers, and industrial electronics.

This microfactory offers a sustainable alternative to manual disassembly or the disposal of equipment through landfilling or incineration, effectively addressing many challenges related to electronic waste disposal. As end users encounter increasing regulations surrounding the responsible management of decommissioned equipment, the automated disassembly process minimizes the risks associated with handling toxic materials that can harm both the environment and human health, while freeing workers from hazardous and labor-intensive tasks.

Additionally, many electronic components contain rare earth elements (REEs), and the microfactory’s automation capabilities enhance the recovery of these valuable materials, presenting an economic opportunity for their reuse in the production of new electronic devices.

The microfactory solution targets hyperscalers with extensive networks of data centers and IT Asset Disposition (ITAD) companies.

"We are excited to have the support of ABB, a global leader in robotics and automation, as we continue to push the boundaries of circularity and automation," said Rob Lawson-Shanks, CEO & Co-Founder of Molg. "With this investment from ABB, we can accelerate our efforts to create more sustainable, circular manufacturing processes for electronics, ensuring that valuable materials remain in circulation and enhancing supply chain resilience."

This solution is part of Molg's broader portfolio, which includes design-for-circularity and component traceability software tools that help manufacturers create products that can be easily de-manufactured and recycled at the end of their lifecycle.

Share: